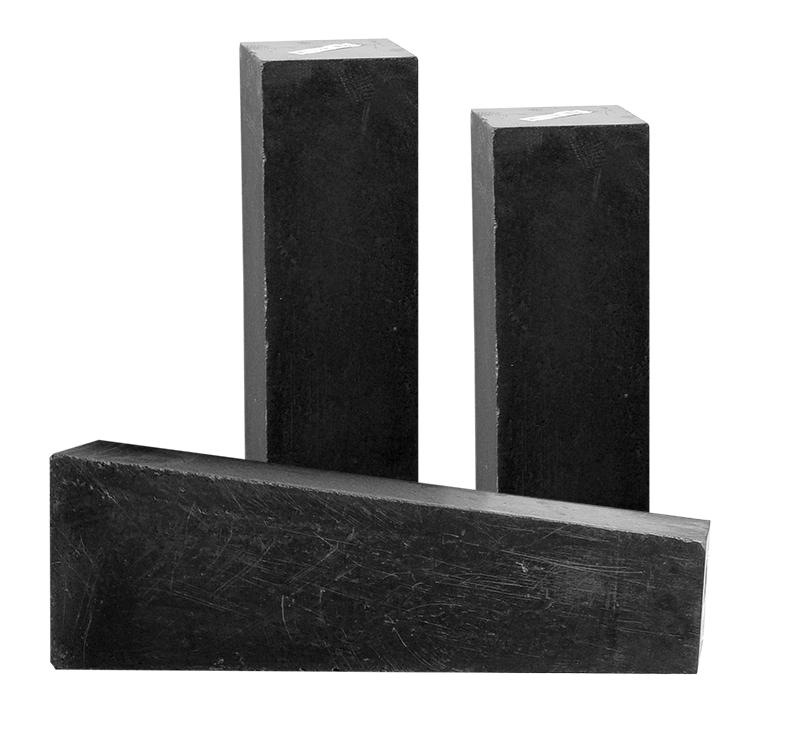

Electric Furnace Magnesia Carbon Brick

Product Description

Electric Furnace Magnesia Carbon Brick

Magnesia-carbon bricks are made of burnt magnesia (or fused magnesia) and carbon materials (mainly crystallized graphite) as raw materials, using resin as a binder to prepare and press, and heat treatment. In order to improve the oxidation resistance, anti-oxidants such as metals are often added. Magnesia-carbon bricks form a carbon skeleton bond when used at high temperatures.

Since magnesium oxide and carbon do not have a mutual soluble relationship, the excellent fire resistance of the original components is retained. Carbon has good thermal conductivity, low thermal expansion coefficient and low elasticity coefficient, which can effectively prevent high-temperature spalling and slag penetration, and is not prone to structural spalling, which greatly changes the fatal weakness of degraded structure spalling caused by slag penetration of magnesia refractories. Coupled with the non-wetting of carbon to slag, the corrosion resistance is also good. These series of characteristics of magnesia carbon brick make it an ideal lining material with good thermal shock stability, corrosion resistance and spalling resistance.

Magnesia carbon bricks

| Brand | MgO (%)≥ | C (%)≥ | Apparent porosity A.P(%)≤ | Bulk density B.D(g/cm3)≥ | Compressive strength at room temperature C.C.S MPa≥ |

| MT-10B | 77 | 10 | 4 | 3 | 45 |

| MT-12B | 75 | 12 | 4 | 2.95 | 40 |

| MT-10A | 80 | 10 | 3.5 | 3.05 | 45 |

| MT-12A | 77 | 12 | 3.5 | 3 | 40 |

| MT-14A | 75 | 14 | 3 | 2.95 | 40 |

| MT-16A | 72 | 16 | 3 | 2.95 | 35 |

Alumina magnesia carbon bricks

| Brand | MgO (%)≥ | Al2O3 (%)≥ | C (%)≥ | Apparent porosity A.P(%)≤ | Bulk density B.D(g/cm3)≥ | Compressive strength at room temperature C.C.S MPa≥ |

| AMT-60 | 16 | 57 | 12 | 4 | 2.92 | 50 |

| AMT-65 | 17 | 62 | 10 | 4 | 2.95 | 50 |

| Type | Magnesia Aluminum Carbon Brick | Magnesia calcium carbon brick | |||||

| Index grade | MAC60 | MAC70 | MAC74 | MGT5 | MGT2 | MGT13 | |

| MgO(%)≥ | 55 | 68 | 71 | 70 | 75 | 70 | |

| Al2O3(%)≥ | 23 | 8 | 6 | - | - | - | |

| C(%)≥ | 8 | 10 | 10 | 5 | 2 | 8 | |

| CaO(%)≥ | - | - | - | - | - | - | |

| B.D(g/cm3) ≥ | 3 | 2.9 | 3 | 2.9 | 2.85 | 3 | |

| Apparent porosity AP(%)≤ | 6 | 5 | 5 | 6 | 7 | 5 | |

| Compressive strength at room temperature CCS(Mpa)≥ | 30 | 35 | 40 | 30 | 30 | 35 | |

Main applications:

Magnesia-carbon bricks have a wide range of uses, and can be used in key parts of thermal equipment such as steel-making converters, electric arc furnaces, ladles, and out-of-furnace refining furnaces. The aluminum-magnesium-carbon bricks made of high-quality bauxite clinker, fused corundum, and fused magnesia have low thermal conductivity, good thermal insulation, and appropriate residual expansion.

They are used for ladle, lower wall, bottom and free Good materials for the department. The performance of magnesia-aluminum-carbon bricks is between that of magnesia-carbon bricks and aluminum-magnesia-carbon bricks. Magnesia-calcium carbon bricks are made of high-quality magnesia, dolomite sand and synthetic magnesia dolomite sand as raw materials, and anhydrous resin as a binder. Good slag resistance, more stable under high temperature vacuum, and can clean molten steel. It is suitable for VOD furnace, AOD furnace and LF furnace of external scouring device.

Product Categories : Magnesia Carbon Brick